|

To Index Home Page

To View

Background Information ONLY

Use your mouse

with the slider on the right of this frame

to view the panels of information which follow.

PRINTOUT PAGEfor Background Informantion

if you wish to print out all the Background Information on the LEFT side of the tutorial,

BUT without the large spaces between images and text,

CLICK ABOVE

Tutorial No.10. - Image 10000b

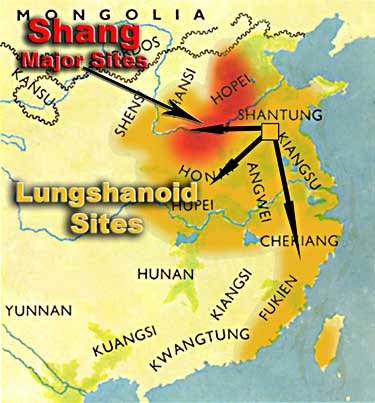

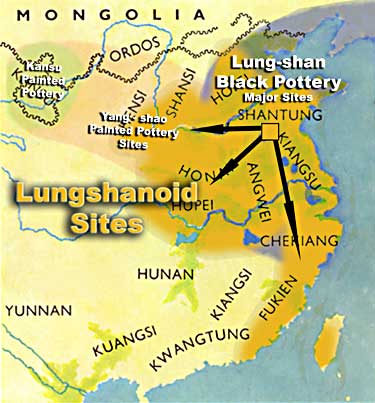

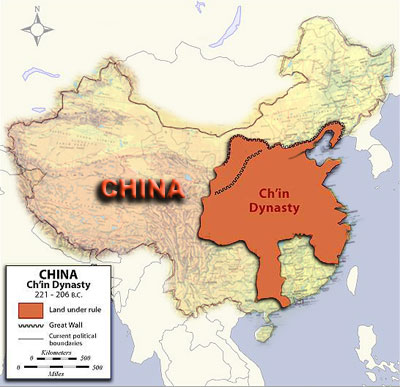

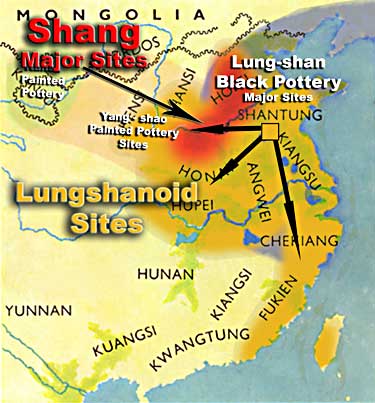

10000b Map of Lung-shan culture

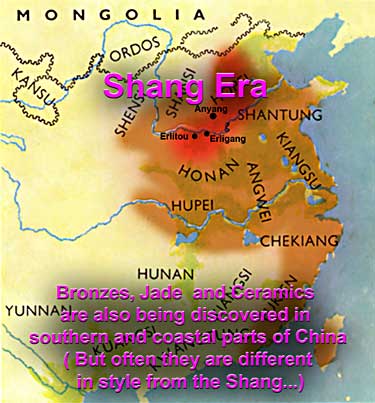

Tutorial No.10. - Image 10000h

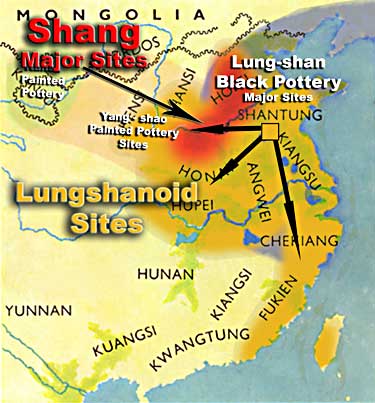

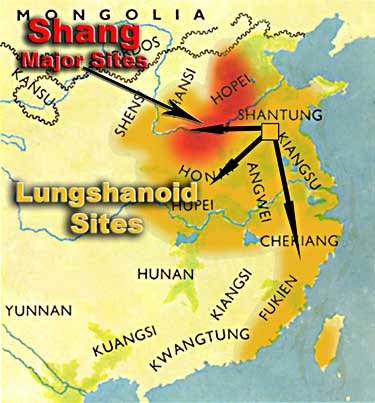

10000b Map showing Shang culture begining to replace Lung-shan culture

Start of Shang Era Background Information

|

The Shang Era - More Background

archeological excavation, ancient hearsay and later texts, support the idea that soon after the beginning of the second millennium BC, one powerful tribe or clan had begun to dominate the area around the middle reaches of the Yellow River valley and eastwards to the Great plain and the Sea. Later when writing was invented, we learn this tribe's name is SHANG.

The Shang first appear at a Lungshanoid site - Erlitou- and began to occupy it around 1800BC. The Shang Clan, Tribe or Family ruled for about 800 years and most later Chinese historians have believed the SHANG to be THE origin of their culture. Only towards the end of the 20th Century AD. have excavations shown this 'single origin' belief to be misleading. Early (Shang)texts suggest that the Shang were all-powerful. Generations of Chinese scholars from Han times to the 20th century have accepted that the Shang culture was the prime origin of the Chinese people and their culture. Increasing archeological evidence of the late 20th century suggests that these early texts distorted the power of the Shang and that many other ethnic and tribal groups within and around China contributed to the evolution and development of a unified culture.By the time of the Han Empire this had blossomed into the rich, powerful and distinctive 'Chinese' culture and has continued to retain its identity and develop though succeeding eras to the present time.

Erlitou

ca.1850BC-1650BC.

Erligang

ca.1650BC-1400BC

Anyang or 'Yin' (Final Phase)

ca. 1400-1123BC

The Shang first appear at a Lungshanoid site - Erlitou-

and began to occupy it around 1800BC. The Shang Clan, Tribe or Family ruled for about 800 years and most later Chinese historians have believed the SHANG to be THE origin of their culture. Only towards the end of the 20th Century AD. have excavations shown this 'single origin' belief to be misleading.

I use the term "Era" because during the last 30 years the earliest origins of "Chinese" Art, Culture and technology are no longer thought to be centred on the last Shang capital.

Through recent excavations it is becoming clear that the Shang had many competitors as they struggled for power, although the earliest writing(Shang texts) imply that the Shang rulers are the greatest power of their Age.

10001a Shang Bronze Halbert Blade ko - 16th-15th century BC.Cheng-Chou, Honan L:20.3cm Info about pic here. 10001a Shang Bronze Halbert Blade ko - 16th-15th century BC.Cheng-Chou, Honan L:20.3cm Info about pic here.

Bronze weapons and tools probably contributed to this conquest. The many smaller clans of Yangshao, Lungshan and other cultures with countless numbers of villages were absorbed and then dominated by Shang overlords. This now became a feudal society: a powerful Priest/King at the top, then Nobles, Barons and a knightly warrior class, with peasants and slaves at the bottom. Power become concentrated in fewer hands.

Metal, above all bronze, became a symbol of this power and wealth. Ritual and useful objects in bronze, silver and gold were produced for the king, the priesthood and the court. There are many similar social developments throughout history.

Three Main Shang Sites

Erlitou was the earliest important Shang settlement perhaps as early as 1800BC. and was occupied until at least 1650BC. Erligang, near Zhengzhou,was the second major Shang site ca.1500-1400BC. The last and greatest of the Shang sites/cities was Anyang(or Yin) ca.1300-1050BC.

Anyang became the greatest of the Shang settlements ca.1300-1050BC Until very recently most of the information about the Shang had come from excavations in and around Anyang.

10103 & 10104. Anyang excavation site in 1920s. 10103 & 10104. Anyang excavation site in 1920s.

Serious archeological excavation of the Anyang site only began in the 1920s Remains of buildings, pit tombs and artifacts from all three Shang sites or cities testify to the growth of an impressive Bronze Age culture.

Bronze weaponry, the key to power, does not seem to be solely a Shang technology. Further south, in the middle of the second millennium BC., magificent bronzes were being made and important ceramic kiln building techniques evolving. Most technologies were by then understood by many tribal groups fighting for power and control in central China during this long period of nearly a thousand years.

To Start of Background Notes

or

|

|

End of Shang Era Background Information

Tutorial No.10. - Image 10001a

10001a Shang Bronze Halbert Blade ko - 16th-15th century BC.Cheng-Chou, Honan L:20.3cm

Tutorial No.10. - Image 10103

10103

Tutorial No.10. - Image 10104

10103

Start of A Written Language Background Information

|

A Written Language

By 1500BC the great pyramids of Egypt were about 1000 years old and writing had began much earlier. In Mesopotamia and Northern India advanced urban literate cultures were well established before 2000BC. In Crete the Minoan Civilization was reaching its peak. In China however the earliest examples of Chinese writing are dated to the late Shang period (ca. 13th-12th centuries BC).

A Record of Chinese History Begins

(ca 1600 BC)

During the Shang Era

Probably a way of making written records began in the early part of the second millennium BC. This consisted of scratched marks which eventually became ideographs(symbols representing numbers, names, places, ideas etc).

The earliest surviving examples so far found are scratched on animal bones and date from about 1600 BC. Such groups of symbols would expand and develop through 3000 years into the Chinese script of today.

LEFT:10013 & RIGHT:10014 Oracle Bones 16th-11th c BC. Excavated in Anyang

LEFT:10013 & RIGHT:10014 Oracle Bones 16th-11th c BC. Excavated in Anyang

In China, the earliest written event, name of a person or object was found marked on large animal bones or tortoise shalls. The earliest of marks on these bones date from about 1600BC. These scratch marks are ideographs, similar in principle but not related to Mesopotamian and Egyptian symbols used for writing. These are the so-called Chinese Oracle Bone Inscriptions (jiaguwen) which were found at the site of the last Shang capital near present-day Anyang, Henan province.

The inscriptions on these bones tell us that by 1200 BC Chinese writing was already a highly developed writing system which was used to record a language fairly similar to classical Chinese. Such a complex and sophisticated script certainly has a history but so far we have found no traces of its predecessors.

10012 Oracle text carved on Large Tortoise shell 16th-11th c BC. Anyang 10012 Oracle text carved on Large Tortoise shell 16th-11th c BC. Anyang

The groups of symbols on the bones and shells have been identified by Chinese scholars as religious texts. They are predictions or oracles by a priest/king and these scratch-marked bones are often referred to as "Oracle Bones". On these were recorded the names of a Ruler/Priest, Chinese Ruling House or Clan; and here was the first mention of the SHANG.

The oracle bone inscriptions received their name after their content which is invariably related to divination. The ancient Chinese diviners used these bones as records of their activity, providing us with a detailed description of the topics that interested the Shang kings. Most of these divinations refer to hunting, warfare, weather, selection of auspicious days for ceremonies, etc

Sometime after 2000BC a form of writing (to record names of gods and rulers, events, lists of things and ideas) evolved in China. This took the form of linear cuts or deep scratches. The earliest examples found were cut into bones or large tortoise shells and date from around 1200BC. By which time this was a highly developed writing system. Unfortunately we have no history of its development. From records and lists we can piece together clues about early Chinese society. The SHANG Kings were the rulers named in the earliest of these bone inscriptions (mid 2nd millennium BC)

.

Most of these processes must have needed some simple symbols and marks for objects, places, quantities etc. Written records soon becomes essential in such a culture. How this began in China is not yet properly understood. But it evolved as ideographs (symbols of ideas, names, objects, places), as had already happened in Mesopotamia and Egypt around 3000BC. In the Mediterranean region ideographic scripts evolved into the alphabetic languages of the Phoenicians, Greeks and Romans. The Chinese language of today is unique in that it is directly related to the script developed in the Shang era 4000 years ago.

To Start of Background Notes

or

|

|

End of Background Information

- Examples of Written Language

Tutorial No.10. - Image 10013

10013 Oracle Bones 16th-11th c BC. Anyang

Tutorial No.10. - Image 10014

10014 Oracle Bones 16th-11th c BC. Anyang

Tutorial No.10. - Image 10012

10012 Oracle text carved on Large Tortoise shell 16th-11th c BC. Anyang

Start of Shang Beehive kiln Background Information

|

Potters Notes:

Shang 'Beehive' Kilns

Possible Reconstructions

From Remains of Foundations

Although only the remains of badly ruined Shang kilns have so far come to light, we can say that their updraft kilns were in essence a similar form to that used in the West.

The question of prime interest is how and when did Chinese potters produce pots fired to temperatures beyond bonfire and earthenware temperatures 900-1050°C.It is said that kiln designs were changing and that a form of down-draft kiln was used. However, unfortunately as yet much of the information about Shang kiln design and firing techniques still seems to be academic speculation rather than hard facts.

Reconstruction Drawings

In her book The Chinese Potter, Margaret Murrey includes drawings of a possible reconstruction of one of these ruined kilns and then goes on to explain how it would have been fired to produce high temperature reduction firings.

10022b Detail: Possible reconstruction of 'Beehive' Shang Undraft Kiln. 10022b Detail: Possible reconstruction of 'Beehive' Shang Undraft Kiln.

there have been attempts to explain how the upper dome of the kiln might have been constructed but there are more questions than answers still about these updraft/downdraft? beehive type kilns. Much seems to me complex speculation.

10022c Detail: Possible reconstruction of 'Beehive' Shang Downdraft Kiln. 10022c Detail: Possible reconstruction of 'Beehive' Shang Downdraft Kiln.

This drawing shows additional outlets in the wall of the kiln, and regulating dampers. The theory is that this was the design of the Shang Downdraft kiln.

To Start of Background Notes

or

|

|

End of Background Information

- Shang Kilns Reconstruction

Tutorial No.10. - Image 10022a

10022a Possible reconstruction of 'Beehive' Shang Kilns.

Tutorial No.10. - Image 10022b

10022b Detail: Possible reconstruction of 'Beehive' Shang Undraft Kiln.

Tutorial No.10. - Image 10022c

10022c Detail: Possible reconstruction of 'Beehive' Shang Downdraft Kiln.

Start of The Shang Bronze Industry and Potters Background Information

|

The Chinese Bronze Industry and High Fire Ceramics

From the early Shang dynasty the local refractory grey clay was exploited for bronze casting moulds and bricks for high temperature bronze furnaces. Bronze-making technology and the convenient presence of an unlimited supply of refractory grey clays in Eastern China were undoubtedly the important factors leading to the making of highfire ceramics by mouldmaker potters working in the bronze industry. We will probably never know in detail how these ceramic discoveries and changes occurred, but the grey clay pottery occurs as the bronze industry appears in the very beginning of the Shang era. The refractory grey clay was essential for making bronze moulds and refractory bricks for high-fire kilns and furnaces. Higher firing temperatures were almost certainly linked to the needs of the bronze industry, but inevitably the fired grey clay became tougher with increases in temperatures from 1100°C to near 1300°C. Moulds and pottery became quite tough. Kilns and furnaces became increasingly efficient and built to stand much high temperatures. Unfortunately, very little remains of early Shang kilns or furnaces to confirm the structural forms. Nevertheless, the very existence of such sophisticated bronze production and high fire potttery must presuppose well-built highfire furnaces and kilns.

10037 Thick-walled stem bowl, impress decorated. 10037 Thick-walled stem bowl, impress decorated.

Such thick walls indicate this to be a fired clay model used for making a piece mould in clay to produce a similar cast bronze vessel. Not many such objects have been found.

No text as yet, has shed any light on the actual relationship between pottery making and the evolution of this amazing bronze industry during Shang and Chou times. Bronze production dominates this long period and it is quite possible that ceramic technology made all this possible. Inevitably, Shang and Chou metal workers and potters must both have shared ideas and expertise with each other.

Clay Models And Moulds Were Needed

Both models and heat resistant moulds needed to be made for producing the final bronzes. Refractory clays were necessary for such piece moulds to withstand the heat-shock of liquid bronze. So the Shang bronze industry needed ceramic models and moulds made by specialised craftsmen who knew about clay and clayworking, i.e. potters.

A Rare Find

A fired clay bronze model

10038 Clay relief model of a monster mask. Eastern Chou Warring States late 5th or 4th c. BC. L.32.8cm. 1959 Hou-ma, Shansi. 10038 Clay relief model of a monster mask. Eastern Chou Warring States late 5th or 4th c. BC. L.32.8cm. 1959 Hou-ma, Shansi.

A rare find, a bronze model, modelled or carved in clay and then used to make the (negative) moulds required for casting. This model represents the initial stage of mould manufacture and shows the high quality of detail achieved by the potter/modelmakers. This is a fine detailed piece of clay carving/modelling typical of the high standard of model making required in this industry.

<

Kiln Bricks and Firing Techniques Needed

Refractory clay bricks and vessels were also needed for furnaces. A mass of pottery making expertise, techniques, materials, kiln and firing technology must have been at the heart of this vast industry;

Did Some Master Potters Switch Jobs?

Looking back, it's pretty clear that master potters didn't die out in the Shang era; many were probably working in the bronze industry from its beginnings. Probably an army of potters would have been needed to make models and carve the great number of complex refractory clay moulds used. Since we know what vast quantities of bronze castings were produced. When you examine all the intricate detail of such bronzes you realise what expertise such potters needed to make such complex models and moulds for the bronzes.

To Start of Background Notes

or

|

|

End of Background Information

Shang Potters and the Bronze Industry?

Tutorial No.10. - Image 10037

10037 White earthenware pottery dou vessel, from Zhengzhou.

Start of Potter's Notes Info on Ceramic Technology - Low-Fire & High-fire Ceramics Background Information

|

Potters Notes:

Ceramic Technology

Low-Fire & High-fire Ceramics

A brief introduction

With the high-fire ceramics of the Shang and Chou potters we enter a new more complex ceramic technology, so perhaps this is the moment to review our technology so far.

Most pottery cultures the world over have made pots and sculpture out of common red clay; e.g. ancient Egypt, Mesopotamia, Crete, Greece, Rome and pre-bronze age China. These were then baked in hot bonfires or simple kilns to about 1000°. In tutorial 4, I wrote about the Earliest Frits and Glazes of the Middle East - these were mostly low temperature high alkaline frits in Egypt and Mesopotamia. A few lead glazed pots do appear in the late Greek and Roman world - lead oxide in white slip - brushed or painted on pots and fired to around 1000°C.

Each of these pottery-making communities eventually learned to avoid much overfiring since the pots could be ruined.

803 Roman red clay lamps over-fired. 803 Roman red clay lamps over-fired.

Most red clay pots, if fired over 1050°C by accident or high winds will distort or collapse. This small pile of terracotta oil lamps was over-fired. They softened, slumped and squashed on top of each other into a useless heap; an ancient firing disaster?

Red Clay Pots Overfired

The photos below demonstrate graphically what happens to red clay pottery if fired much above 1050°C. Progressive distortion, collapse and slumping into a heap - well before 1200°C is reached.

The last illustration above and one below show the result of firing to 1260°C a refractory firebrick with a small lump of red clay on the top; The firebrick is unaffected but the red clay has become a pool of molten brown-black glaze.

10119c-d Small pieces of red clay resting on firebricks 10119c-d Small pieces of red clay resting on firebricks

The right-hand image shows the piece of red clay melted into a dark chocolate coloured glaze by 1260°C

Ceramic Fluxes and Glaze Melting Points

At the heart of glaze study is the effect of heat on a relatively small range of compounds and minerals and in particular the fluxing effects of a few oxides which can lower dramatically the temperature at which very refractory silica melts into a glass.

The Essential Quality of a Ceramic Glaze

A stable, usable ceramic glaze can be defined as a form of glass which when molten does not then run like honey down the side of a pot. A reliable glaze melts into a smooth glass and remains in position on the pot like a thick coat of grease or thixotrophic paint over a few degrees range. When cool, it solidifies into a hard glassy coating.

|

A Glaze Recipe v Ratio of Glaze Oxides?

A potter who wishes to understand and make his/her own glazes needs some understanding of simple chemistry terms and the symbols for elements and compounds.

Some materials in a glaze recipe are single compounds; sand for example is Silica or silicon dioxide SiO2. However; materials such as clay or wood ash are mixtures of many different compounds.

The heat of even earthware firings decomposes most materials in a glaze recipe into simpler compounds and so fortunately we are usually left with a collection of simple oxides to consider in a glaze - such as K20, Al203 and Si02.

A 19th century German chemist called Hermann Seger devised a system for predicting the way a glaze would behave according to the proportions of Silica, Alumina and Flux oxides in the recipe. Many potters and industries use such a system still. To read about all this in greater detail find books on glazes, bodies and kilns by Daniel Rhodes and others - try a search through Amazon.co.uk.

The Essential Glaze Oxides

SILICA SiO2 - (THE GLAZE MAKER) Sand, quartz, flint are all forms of silica. It is a very refractory material. Heated alone silical will only melt into a glass at about 1710°C. No pottery kilns reach this temperature!

CERAMIC FLUX(ES) - certain mineral oxides which will cause silica to melt into glass at much lower temperatures.

The most common and powerful ceramic fluxes are: Potash K2O, Soda Na2O (They are known as the alkalies), and Lead Oxide PbO. - These three ceramic fluxes can produce a glass with silica at temperatures below 1000°C. Another common glaze oxide is Lime CaO. But only useful as a powerful flux only at higher temperatures. Iron - FeO.(Black), Fe2O3 (Red), can have a fluxing effect at higher temperatures apart from its effect on colour. There are other oxides which act as ceramic fluxes.

ALUMINA Al2O3 - (THE STABILIZER) A very refractory mineral oxide(only melts at about 2050°C) which thickens or stabilizes the (fluid) glass into a (less fluid) glaze.

There often additional oxides present which can modify the glaze colour, texture etc., but silica, fluxes and alumina are the essential oxides and always present.

LOW FIRE GLAZES ca. 800-1060°C need large amounts of one or more powerful fluxes such as Potash, Soda or lead oxide to cause the silica to melt into a glass at such temperatures. Low temperature glazes need only a very little alumina to stiffen or stabilise.

HIGH FIRE GLAZES ca.1180-1300°C need smaller amounts of powerful fluxes such as potash or soda. Glazes which melt at 12-1300°C. often include a high amount of lime since at high termperatures it becomes as powerful as lead or potash in fluxing silica to melt. More alumina is needed to stiffen high fire glazes.

|

|

Clay Bodies

Low Fire & High Fire

Firebrick and melted red clay pot Firebrick and melted red clay pot

Absolutely pure clay(china clay, kaolin)Al2O3.SiO2.2H2O is too refractory a material to use alone for pots. Every clay body needs a sufficient amount of ceramic flux(s)to bond the particles together permanently when heated to a particular temperature, called its maturing point. When cold it become a permanent "ceramic" form. Now look at the firebrick fired to 1260°C, it is very hard and has retained its shape after constant firings to this temperature. 1200-1400°C is its maturing temperature range. Now consider the pool of melted red clay, 1260°C is way beyond its maturing temperature of about 900-1050°. The much higher amounts of potash, lime and iron in the red clay body have fluxed the silica present into a glaze when fired to such a high temperature; the fireclay contains only a trace of potash, lime and iron, just sufficient to melt some grains of sand just enough to bond all the particles of the body together and produce a tough refractory brick.

What is in a natural clay body?.

All natural clay bodies contain pure clay/kaolin/china clay. However, they all contain in addition many other mineral impurities such as sand, iron and lime depending on the geology of the area in which they are found.

In common dark coloured natural clays such as red and brown, green and yellow ochreous clays, there are high amounts of iron and lime

and usually some alkaline oxides too. Such clays are likely to produce low fire earthwares.

Many, but not all, pale buff and grey clays are low in iron, lime and alkalies. Such bodies are therefore more refractory than the strongly coloured clays and often make good high fire stoneware bodies.

Remember though, these comments are only a rough guide, not an absolute rule. In practice, plasticity, shrinkage and firing tests should be made on all new clay samples before going into production with a new body.

What is in Wood Ash

Wood Ash is the residue left behind when wood burns. It is a finely powdered mixture of charcoal and a variety of compounds( mostly oxides) depending on the wood. There is always a large amount of silica SiO2 present in plants and therefore found in wood ash. A small but significant amount of alkali is present, usually potash(potassium oxide K2O). Lime(Calcium oxide CaO)is always present too. In any heap of wood ash there is always a high proportion of fine sand(silica SiO2) and clay dust - chemically combined alumina, silica & water - Al2O3,2SiO2,2H2O. Other oxides usually present in small amounts are iron oxide and phosphoric oxide. Look in Leach's A Potter's Book for an interesting list of wood ashes

Wood-fired Kilns

In simple earthnwere kilns the low heat has no effect on wood ash which remains in the firebox or blows as dust through the kiln and is not noticed.

However, in wood-fired kilns capable of reaching temperatures of 1100-1280°C. the tiny amounts of alkalies and lime in wood ash become fluxes. they melt and vapourise and attack any hot clay surface - red hot kiln walls or pots. The constant flow of fine wood ash through a kiln begins to have a glazing effect on the kiln walls when temperatures reach upwards of 1150°C. The effect is slight, but after many firings this can produce a heavy build-up of glaze on the inside walls of the kiln and could drip onto the pots. Any experienced potter who works with high temperature woodfired kilns would soon become familiar with this increasing build-up of a gloss on parts of the kiln walls and after prolonged use it would eventually drip onto the pots below.

This is undoubtedly how woodash glazes were discovered - in Shang China, probably before 1500BC.

An example of a self-glazing woodfired kiln

10120 Woodash glazed bagwall. 10120 Woodash glazed bagwall.

In a wood fired kiln, fine wood ash will be blown from the firebox through the kiln by the through draft. I photographed this fragment of the old Bagwall from a large downdraft kiln in Les Landes, France, producing stoneware tiles and using waste sawdust as fuel. A bagwall separates the firebox from the main kiln chamber and is probably the hottest part of the kiln. This one was made from large hollow extruded building blocks in local stoneware grey clay. It had eventually become covered with ash glaze from the sawdust fuel and had been replaced. I thought it an excellent example to illustrate this effect. The next detail of this bagwall shows the variety of glassy colour and texture which occurs with woodash glazes on coarse stoneware clays.

10121 Info about pic here. 10121 Info about pic here.

Part of the bagwall above,

A Woodash glazed test bowl

10119e woodash becomes a glaze at 1260°C. 10119e woodash becomes a glaze at 1260°C.

A brushed on slip of sieved bonfire woodash becomes a dull greenish glass/glaze at 1260°C. This is a small test bowl with a slip of mixed woodash painted on. After a reduction firing to 1260°C. it becomes a glassy glaze. The black/brown/green centre is the result of adding a brushstroke of red iron oxide on the dry woodash slip before firing - to check the colour response of iron.

To Start of Background Notes

or

|

|

End of Potter's Notes Info on Ceramic Technology - Low-Fire & High-fire Ceramics Background Information

Start of Potter's Notes Info on Chou Potters produce high fire glazes

|

Potters Notes:

Chou Potters produce high fire glazes

based on simple mixtures of

Wood ash, Lime and Clay

The first highfire glazes were undoubtedly accidental and the result of heavily used woodfire kilns; woodash vapourized in the firebox, was blown through the kiln and gradually produced a glaze on the brick walls of the kiln - and a light sheen to the pots. Over 1150°C many of the compounds present in the wood ash dust begin to vapourise and dissociate. The relatively small amounts of flux oxides present in woodash (potash, calcia etc.) become very active and with silica and the surface clay and sand of the kiln bricks soon form a glassy glaze. Such effects are slight but cumulative.

Although bronze continued to be the pre-eminent material for many hundreds of years of the long Shang and Chou eras, potters appear to have slowly but increasingly explored the effects of highfire on various common ceramic materials. During the Chou period in different areas of China large woodfired kilns were regularly producing highfire pottery and begining to make highfire glazed ware that was unique in the world - and would remain so for much more than a thousand years.

Wood ash/lime Glazes

The basis for these early high-fire glazes was a varying mix of woodash, clay and lime(calcium oxide CaO).

Wood Ash(fine sieved) came from the kiln firebox.

Clay - various clays would have been used. Some clays could contain iron or lime, or both.

Lime(calcium oxide)might come from the clay, but could be added as a common calcium mineral such as chalk, whiting, powdered limestone or marble. Such fine powdered calcium minerals have often been used by potters as a white paint(often mixed into a clay slip) to decorate earthenware pottery.

Some Simple Glaze Tests

These Chou glazes were made from simple recipes based on common materials the potters already used. Such early high fire glazes can be emulated by any potter today. With some trial and error testing a range of high-fire glazes can be produced from two or three materials using:

(1)various smooth clay slips

(2) sieved wood ash,

(3) A common chalky material - powdered chalk, whiting, limestone or marble dust.

My three glaze test examples below illustrate the qualities achieved with simple china clay/whiting/woodash mixtures on a grey stoneware body fired to 1260°C in light reduction atmosphere firings in a gas kiln.

xxxx1 Ash/lime glaze test 1. xxxx1 Ash/lime glaze test 1.

The oily runs are characteristic of lime/wood ash glazes. A spiral brushstroke of iron oxide slip painted on the dry glaze towards the centre of the this little test bowl shows the effect of iron on the glaze - it increases the fluidity and produces a dark brown-black glaze.

xxxx2 Ash/lime glaze test 2. xxxx2 Ash/lime glaze test 2.

The oily runs are quite clear in the large illustration. Notice the effect produced by an iron-bearing sand in the clay body and the dull soft frosty shine of a green grey glaze. The lime-woodash glazes of Chou and Han have much in common with this.

xxxx3 Ash/lime glaze test 3. xxxx3 Ash/lime glaze test 3.

The bands of red iron slip painted on the pot before glazing have caused an interesting and characteristic matt crystalline effect where the iron stroke was heavy.

Compare these glaze surfaces with those of the glazed Chou pots illustrated in this tutorial and elsewhere.

To Start of Background Notes

or

|

|

End of Potter's Notes Info on Chou Potters produce high fire glazes

Tutorial No.10. - Image 10119a

Info underneath pic.

Tutorial No.10. - Image 10119b

Info underneath pic.

Tutorial No.10. - Image 10119c

Info underneath pic.

Tutorial No.10. - Image 10119d

Info underneath pic.

Tutorial No.10. - Image 10119e

Info underneath pic.

Tutorial No.10. - Image 10120

Info underneath pic.

Tutorial No.10. - Image 10121

Info underneath pic.

Tutorial No.10. - Image 10020

10020 Text Culture. Ht:.cm. ca.BC. MMM

Tutorial No.10. - Image xxxx1

xxxx1 Text Culture. Ht:.cm. ca.BC. MMM

Tutorial No.10. - Image xxxx2

xxxx2 Text Culture. Ht:.cm. ca.BC. MMM

Tutorial No.10. - Image xxxx3

xxxx3 Text Culture. Ht:.cm. ca.BC. MMM

|

The Chou Era

Western Chou 1027BC to 771BC

Towards the end of the second millennium BC.the Shang priest/king rulers lost contol to another tribal family group - the CHOU. This now became a purely feudal state. The King's land was in the centre surrounded by great estates of his principal vassals which were bordered by other smaller states. In reality a number of the most powerful vassal princes controlled the heart of China -"The Middle Kingdom" in a fashion (not unlike later Mediaeval Europe in the first millennium AD).

Eastern Chou 770BC to 256BC

Following the removal of the capital to Loyang in 770BC., royal land was reduced and the Chou king became just a religious figurehead with little power. Bronze and other metals continued to be the preferred materials for most religious and ceremonial objects. Potters with any talent probably continued working in the burgeoning bronze industry making clay models, and moulds for bronze casting. Two sets of State records from the Chou Age are our main source of information

"Spring& Autumn Annals" 722-481

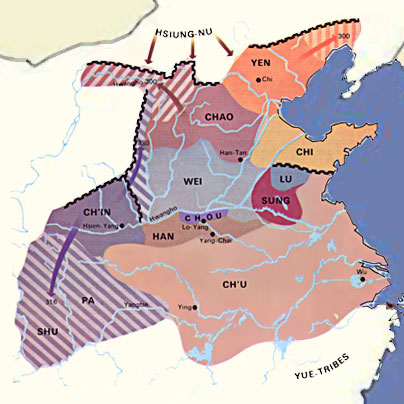

During the Spring and Autumn Annals period, there were over 150 kingdoms coexisting with Chou, among them Chi, Lu, Jin, Yan, Ch'in, Chu, Wu, Yue, etc were the stronger. These powerful states, relying on their military and economic advantages, launched wars to expand their territories, forcing small states to follow them so as to establish their dominance as overlords. According to historical records, during this period, a total of thirty-six kings were killed and fifty-two vassal states disappeared. This constant conflict and annexation of one state by another during the Spring and Autumn Period hastened social and economic change and had the effect of integrating people of different tribes and nationalities.

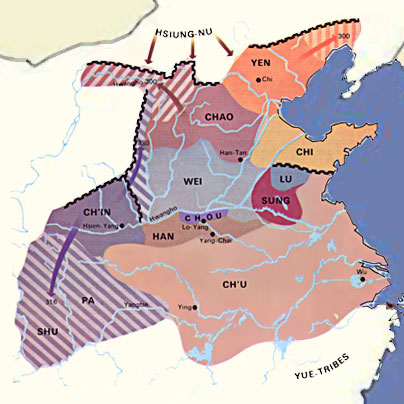

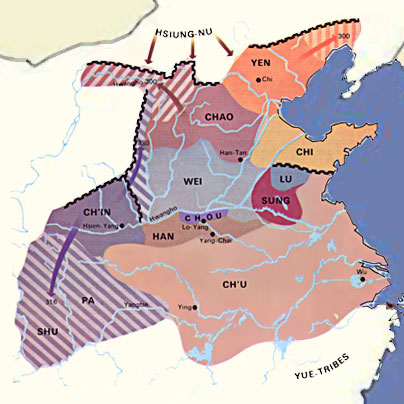

"Warring States" Period; 476 BC - 221 BC

By the 5th century BC many areas were distressed by wars between the large feudal lords with great territories. The Chou royal land had shrunk to a small state at the centre of the 'Middle Kingdom'; The King now had little power. The feudal lords fought with one another or with the nomads at the borders.

The consequence of this period of drastic upheavals, reshufflings and re-groupings, what had been several hundred states were reconstituted into seven mega-states. China entered the Warring States Period. After long-term wars, seven kingdoms, namely Chi, Chu, Yen, Han, Chao, Wei and Ch'in, appeared as the most powerful states in this period, known as the "Seven Overlords" in history. To expand their forces and territories, the seven overlords, on the one hand, carried out reforms in their own states to strengthen themselves and, on the other, were warring against each other and scheming to annex other states, which gave rise to the situation of seven powerful states existing side by side and struggling against each other. Riches and wealth often changed hands. The merchant class increased in importance as did the bourgeoisie and administrators in the cities.

To Start of Background Notes

or

|

|

End of The Chou Era background Information

Tutorial No.10. - Image map

Tutorial No.10. - Image map

|

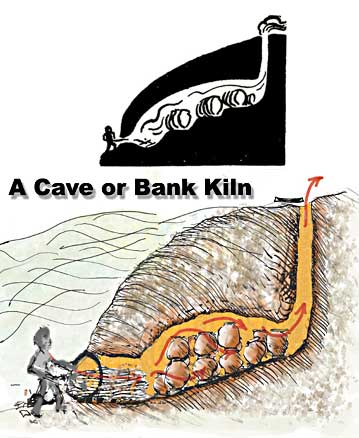

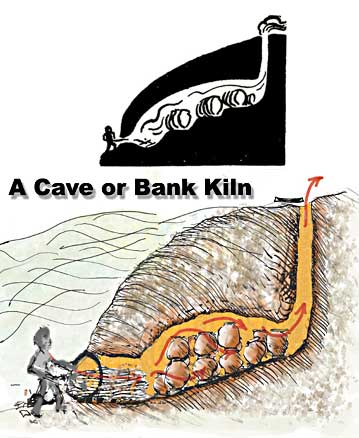

The Oriental Cross-Draft Kiln -

Variously called:

Hole, Cave, Bank or Climbing kiln

This most important ceramic invention was the extraordinarily simple kiln dug out of a hillside, variously called, Hole, Cave, Bank or Climbing kiln. It is now often referred to more prosaically as 'the original Oriental Cross-Draft Kiln'. There is a recorded tradition of this type of kiln in Japan and Korea from about 5th century AD. As far as I am aware no excavations in China have yet discovered the remains of a cave kiln from Shang or Chou times. But given the continuous ceramic history of high-fire pottery in China, this type of kiln probably originated here - though perhaps it was not in the north but the southern provinces towards the coast.

10009 Drawing of a Japanese/Korean 'Cave' Kiln. 10009 Drawing of a Japanese/Korean 'Cave' Kiln.

The 20th century english potter Bernard Leach was probably the first westerner to write about these kilns:

Leach: "...The bank or climbing kiln originated in the Far East: a cave was dug in the sharp fall of an earthy bank, a small doorway was left as a stokehole or furnace mouth, and at the opposite end an opening was dug through to the surface as a chimney. The floor was stepped, and the pots were piled on the level terraces, the flames passing around and over them".

The Japanese potter Tomimoto Kenkichi related his theory on the development of this type of kiln.

"...Pottery villages were built upon their clay source and utilised the banks and hills of clay to hollow out such large holes...

Glaze deposits(wood ash slag) formed on the chamber walls and roof as the kilns begame hotter and were fired longer...

Eventually the wood ash slag would drip off onto the pots..."

Fred Olsen in his 'The Kiln Book' Assumes that China, Korea and Japan simultaneosly developed similar cross draft kilns... Kilns known as bank or hole kilns. ...Hole kilns were in use ca. 500AD during the Asuka period in Japan, Sui period in China, Silla period in Korea. ...In Japan called Anagama (hole + kiln)..."

We can expect the continuing excavations will shed more light on the intriguing origins of this type of kiln. Cave kilns have such a minimal structure, that after all this time most will have disintegrated leaving little or no traces above ground. However, eventually, I believe, remains of such kilns from the Chou period will be found in China, probably in the south east provinces.

To Start of Background Notes

or

|

|

End of Background Information

-xxxxxxxxxx

Tutorial No.10. - Image 10009

10009 Text Culture. Ht:.cm. ca.BC. MMM

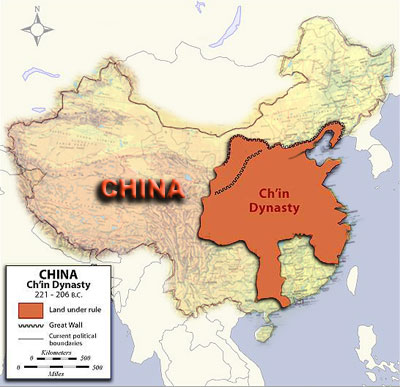

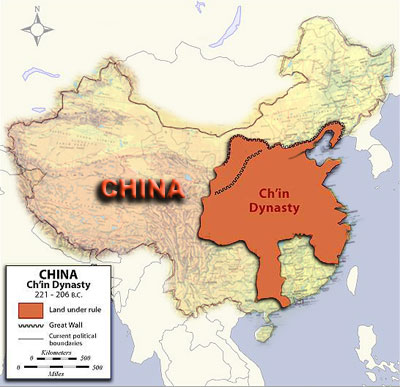

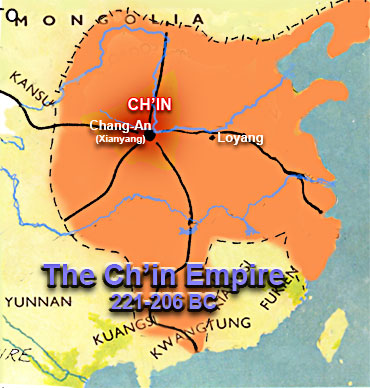

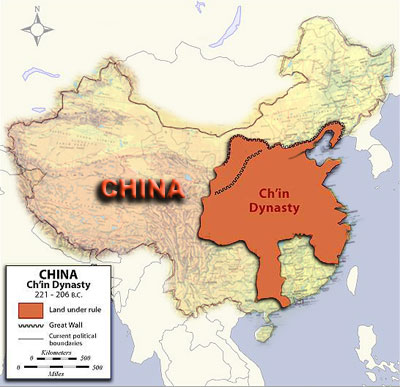

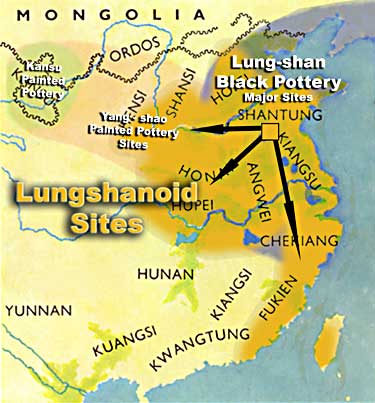

Tutorial No.10. - Image China-Map-Chin-Empire

Map of China showing the approximate area of the territory ruled by Shi Huangdi, the First Emperor of China

Tutorial No.10. - Image China-Map-Chin-Empire

Map of China showing the approximate area of the territory ruled by Shi Huangdi, the First Emperor of China

|

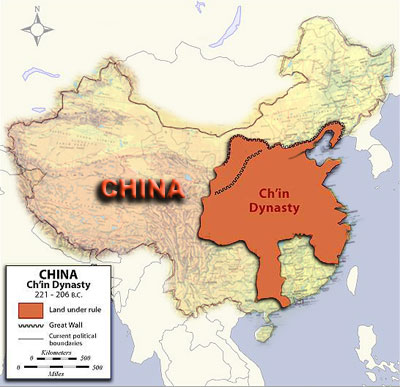

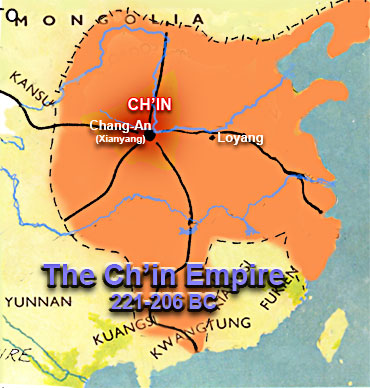

The Ch'in Empire Background

The Victory of the Ch'in 221BC Led by Shih Huang Ti - The First Emperor

During the Warring States Period, Ch'in, because of its outlying position, was more backward than the states in the Central Plains.

Ch'in, based on the reforms and improvements, quickly became a powerful state, laying a solid foundation for the future unification of China by Emperor Chin Shi Huang.

In 256 BC, Ch'in dispatched an army and defeated the Eastern Chou Dynasty. Before long, after King Yingzheng succeeded to the throne, he expedited his project of annexation and finally in 221 BC. united central China and established a unified, multi-national, autocratic and power-centralized state, putting an end to the Warring States Period. From a ceramic point of view his short reign(221-206BC) is memorable for the vast underground chamber containing an army of near life-size terracotta figures which he caused to be made for his tomb complex.

To Start of Background Notes

or

|

|

End of Background Information

-xxxxxxxxxx

Tutorial No.10. - Image Ch'in Map1

10110 Text Culture. Ht:.cm. ca.BC. MMM

That was the last illustration.

I hope you have found Tutorial No.10 interesting and perhaps useful.

The next Tutorial No.11 is the third tutorial of eight on Chinese Ceramics.

That was the last illustration in this tutorial

revision date at the top of page

Victor Bryant ©1994,2006

To Index Home Page

|

|

Firebrick and melted red clay pot

Firebrick and melted red clay pot![]() 10120 Woodash glazed bagwall.

10120 Woodash glazed bagwall. 10121 Info about pic here.

10121 Info about pic here. 10119e woodash becomes a glaze at 1260°C.

10119e woodash becomes a glaze at 1260°C.