To Index Home Page

Ceramic Web Page Tutorials

[

10

]

Chinese Ceramics 2.

From the Shang Era to the Ch'in Emperor

ca. 1600BC to 200BC

by Victor Bryant

Last added-to or revised 14th September 2006 V.19

PART II Tutorials 1. - 7. CERAMICS IN CHINA

If you just want to see the ceramics

or make a quick survey of the images:

Scroll down through this main text page,

click on a thumbnail image which interests you;

a larger image will appear in the left frame.

![]() -More Info

-More Info

![]() -Picture Reference

-Picture Reference

Ends and Beginnings

New Techniques, New Materials...

...Strife and conquest?

![]() By the early second millennium BC. in north-eastern China, village communities and tribal clans seem to have become absorbed into a larger, more hierarchical, society led by powerful Priest/King/Warriors. Also, recent excavations suggest that the "Lung-shan culture" spread outward from Shantung province by the beginning of the second millennium BC. Similar ways of working and living have been found much further south: along the Yangsi(Blue) River and south-eastwards along the coast. These variants of the Lung-shan style have been termed Lung-shanoid, see map.

By the early second millennium BC. in north-eastern China, village communities and tribal clans seem to have become absorbed into a larger, more hierarchical, society led by powerful Priest/King/Warriors. Also, recent excavations suggest that the "Lung-shan culture" spread outward from Shantung province by the beginning of the second millennium BC. Similar ways of working and living have been found much further south: along the Yangsi(Blue) River and south-eastwards along the coast. These variants of the Lung-shan style have been termed Lung-shanoid, see map.

Lung-shan pottery(Late Neolithic Era) showed new inventive styles.![]() Thrown shapes were refined and complex; usually pots have a suberb black finish. This was achieved by well controlled firing techniques using improved kilns. In addition, there was an unusual handbuilding style

Thrown shapes were refined and complex; usually pots have a suberb black finish. This was achieved by well controlled firing techniques using improved kilns. In addition, there was an unusual handbuilding style![]() in pale grey/white bodies with echoes of beaten metal forms suggesting they had contacts with a metalworking people.

in pale grey/white bodies with echoes of beaten metal forms suggesting they had contacts with a metalworking people.

The Shang Era

![]() The Shang first appear at a Lung-shanoid site - Erlitou-

and began to occupy it around 1800BC. The Shang Clan, Tribe or Family ruled for about 800 years and most later Chinese historians have believed the Shang to be the only origin of their culture. Only towards the end of the 20th Century AD. have excavations shown this 'single origin' belief to be misleading.

The Shang first appear at a Lung-shanoid site - Erlitou-

and began to occupy it around 1800BC. The Shang Clan, Tribe or Family ruled for about 800 years and most later Chinese historians have believed the Shang to be the only origin of their culture. Only towards the end of the 20th Century AD. have excavations shown this 'single origin' belief to be misleading.

10001 Wheelmade dish on high ring cut feet - p’an - 3rd to early 2nd Mill. BC Lung-shanoid(Erlitou)Culture. Ht:11cm.

10001 Wheelmade dish on high ring cut feet - p’an - 3rd to early 2nd Mill. BC Lung-shanoid(Erlitou)Culture. Ht:11cm.

The earlier Lung-shan either evolved into the Shang, or more likely they were over-run by this new force and their settlements taken over by the Shang. In any case, archeological evidence shows that Lung-shan settlements became early Shang sites. This Lung-shan type bowl was found at the lowest(earliest) levels of the Erlitou site. It has the characteristic high quality black finish. Its thrown, rib-decorated form and ring-foot cut into 3 segments makes it a refined and austere piece. It was probably made before 2000BC.

![]()

![]() LEFT: 10002 Lidded tripod jug in low fired white-ish body, Erlitou, ca.2100-1650BC. Ht:20cm. RIGHT: 10003 Angular tripod jug, scratch marked handle, light buff body, Erlitou, ca.2100-1650BC. Ht:18cm.

LEFT: 10002 Lidded tripod jug in low fired white-ish body, Erlitou, ca.2100-1650BC. Ht:20cm. RIGHT: 10003 Angular tripod jug, scratch marked handle, light buff body, Erlitou, ca.2100-1650BC. Ht:18cm.

Both of these handbuilt three legged jugs are from the Erlitou site during the early part of the 2nd millennium. This is the early Shang period. A pale grey clay body is being used. Though different styles, they are both crudely angular and echo or imitate metal forms. The sophistication of the black thrown ware is now gone, but the older tripod form is evolving into something new.

Early Bronze Age

An Important Discovery at Erlitou![]() 10004 An early bronze three legged long spouted, side handled jug, Erlitou, ca.1600BC. Ht:13.3cm.

10004 An early bronze three legged long spouted, side handled jug, Erlitou, ca.1600BC. Ht:13.3cm.

This is one of the earliest examples of metal casting in China. This is made in bronze, an alloy of copper and tin. Although in poor state today, this small metal jug confirms an established BRONZE AGE and displays all the characteristics of Chinese metallurgy, especially the technique of upside-down casting in segmented clay moulds(piece moulds).

These photographs illustrate the close links between Shang Bronzes and earlier ceramic forms. The older forms in clay have been reworked by the Shang bronze makers to become precious ceremonial/religious objects. This new material will replace pottery for important ceremonial utensils for over a thousand years.

These photographs illustrate the close links between Shang Bronzes and earlier ceramic forms. The older forms in clay have been reworked by the Shang bronze makers to become precious ceremonial/religious objects. This new material will replace pottery for important ceremonial utensils for over a thousand years.

A Written Language

Ceramics in the Shang Era

Loss of Status

Simple cooking and storage pottery

![]() 10011 A pottery steamer,hsien, with corded surface. Erligang, Zhengzhou, Honan Ht:45cm. 16-15th c BC.

10011 A pottery steamer,hsien, with corded surface. Erligang, Zhengzhou, Honan Ht:45cm. 16-15th c BC.

With the demise of the Lung-shan culture, ceremonial and ritual vessels were now made in bronze not pottery. Shang pottery is generally undecorated cooking, food and drink utensils in the traditional (neolithic) styles. A good cooking pot, very suitable for slow cooking. The light greyish or buff( refractory) clays common in the Great Plain of Eastern China were now the usual materials for pottery making.The body is in fact coarse particled and fairly refractory. Both properties would contribute resistance to heat cracking, so the pot is an ideal steamer cooking pot. Of course it would still be somewhat porous until the pores were filled with greasy liquid and then carbonised particles during cooking! Notice the deeply scratched texture and that in contrast to earlier versions of the ting form, the rim was finally smoothed and finished on a wheel. Firing temperatures appear to have progressively risen during the early centuries of Shang rule.

1010 Tripod cooking pot in coarse grey body, corded decoration. Shang 12th-11th c.BC. BM.

1010 Tripod cooking pot in coarse grey body, corded decoration. Shang 12th-11th c.BC. BM.

Made some centuries later it emphasises the continuing tradition of the stone age coiled shapes in domestic pottery. Its presence in a grave suggests that it was used for cooking sacrificial meat.

10102 A collection of later thrown earthware food and drink vessels

10102 A collection of later thrown earthware food and drink vessels

In the latter part of the Shang Era a wider range of wheel-made domestic ware appeared. Nevertheless these are still rather uninspired forms lacking any refinement or decoration. Red earthenware is less used; the grey(more refractory) clay was much more common and at higher firing temperatures produced more durable pots.

Shang Ceramic Kilns

Uncertainties & Reconstructions

The construction and working of any Shang kiln is not yet fully explained or understood. Some form of updraft beehive type kiln was in use, but surviving kilns on excavated sites so far have been little more than foundations and ruins.

Shang 'Beehive' Kilns

Projected Reconstructions

Updraft or Downdraft?

10016 Earthenware storage jar,.guan-LEFT and

10016 Earthenware storage jar,.guan-LEFT and

10017 food bowl,gui RIGHT.

10017 food bowl,gui RIGHT.

Common pots - simple decoration:

Left Example: Scratched marks and clay pellets between wheel-grooved bands. Right Example: Impressed linear pattern using a clay roller. Here the body appears more fine particled, but is basically still the same type of pale refractory clay commonly in use. We would probably describe it as a high earthenware/stoneware body. These pots were fired to at least 1050-1150° in a neutral/oxidized firing. Such pots would be quite tough hardwearing cooking or storage ware - with not much porosity.

Note:Such a body would also be excellent for making refactory moulds for bronze casting.

The Chinese Bronze Industry and High Fire Ceramics

Clay Models and Refractory Moulds Needed

![]() 10027 Bronze four-legged ritual food vessel ca.1600BC-1400BC. Erligang, Zhengzhou, Honan Ht:100cm.Wt:86.4kg.

10027 Bronze four-legged ritual food vessel ca.1600BC-1400BC. Erligang, Zhengzhou, Honan Ht:100cm.Wt:86.4kg.

The size and weight of this gigantic ritual food vessel indicates the metallurgical expertise achieved by Shang bronze makers. This object is 1 metre high and weighs 86.4 kilos. The process of designing and producing such a large casting would be no easy task even today with all our skills and equipment.

A Rare Find

A fired clay bronze model

10038 Clay relief model of a monster mask. Eastern Chou Warring States late 5th or 4th c. BC. L.32.8cm. 1959 Hou-ma, Shansi.

10038 Clay relief model of a monster mask. Eastern Chou Warring States late 5th or 4th c. BC. L.32.8cm. 1959 Hou-ma, Shansi.

A rare find, a bronze model, modelled or carved in clay and then used to make the (negative) moulds required for casting. This model represents the initial stage of mould manufacture and shows the high quality of detail achieved by the potter/modelmakers. This is a fine detailed piece of clay carving/modelling typical of the high standard of model making required in this industry.

Bronze Forms in Clay

The potters, who made such vessels as these illustrated below, must have been employed within the bronze-making industry; the forms and decorations are so close. Why they were made is not clear - possibly prototypes for bronzes?

![]() 10078 Dark grey earthenware jar. Shang. H:15.9cm. BMFA

10078 Dark grey earthenware jar. Shang. H:15.9cm. BMFA

This is a sophisticated example: generous, globular middle with simple lugs and a decorative band of scratched marks; neck banded with deep grooves; an added foot, well-turned, cone shaped, smooth blackish finish. This adds up to a bold form which seems to echo both the neolithic Lung-shan tradition and the contemporary bronze forms. The final brown metallic surface has probably been achieved by being brushed with an iron rich clay slip and fired to 1050-1100° in a reduced(smoky) atmosphere.

![]() 10077 Grey pottery jar imitating the form of a bronze tsun type ritual cup.Shang ca.16th Century BC. MMNY

10077 Grey pottery jar imitating the form of a bronze tsun type ritual cup.Shang ca.16th Century BC. MMNY

This goblet copies the form of a bronze tsun type ritual cup. In a similar fashion, potters of the European Bronze Age often imitated metal shapes. Once again, I find echoes of the much earlier sophisticated Lung-shan black ware in this simple elegant form made centuries later.

![]() 10023 A high-fired jar lei with carved decoration. 13th-11th century BC Hsiao-t'un near Anyang. Ht:32.6cm. FGW.

10023 A high-fired jar lei with carved decoration. 13th-11th century BC Hsiao-t'un near Anyang. Ht:32.6cm. FGW.

This impressive carved ceramic jar leiin a fine-grained pale, almost white, body is closely related to current ritual and ceremonial Shang bronzes. The body is high in china clay but does not contain any feldspathic minerals. It is not porcelain, but a fine iron-free stoneware or high earthenware body. Such a body is refractory, not very plastic and brittle when fired. Not surprisingly, it is the only one found complete so far. The walls are thick. It was probably partly coiled, partly thrown and then finished on a wheel. After carving it was fired to 1050-1150°C.

10024 Detail of carved decoration.

10024 Detail of carved decoration.

The decoration was carved into the thick, leather-hard body and the blade marks can be clearly seen. The main decoration on the belly of the pot is a zig-zag banding of a squared spiral, or meander, motif. On the shoulder is the 'monster motif' t'ao-t'ieh.

10025 Detail of 'monster motif'.

10025 Detail of 'monster motif'.

A similar 'monster motif' is carved on the lugs which, whilst still leather-hard, were fixed on with slip. However, the lugs on bronze vessels are usually made separately and fixed on later, so the purpose of this vase remains unclear.

Ceramic Technology

Low-fire & High-fire Ceramics

Shang Potters are the first to discover

Wood Ash produces a gloss/glaze

![]() 10021 Hand-built vessel with flared neck. Ming-kung-lu, Cheng-chou, Honan Shang Dyn 16th-15th century BC Ht:28.2cm.

10021 Hand-built vessel with flared neck. Ming-kung-lu, Cheng-chou, Honan Shang Dyn 16th-15th century BC Ht:28.2cm.

Although dating from the Shang period, this pot appears to be a traditional(neolithic) coiled earthware pot decorated with impressed 'basket' or 'fabric textures' using a little patterned roller. The finish appears buffed and polished. BUT all is not what it first appears...

![]() 10021d Detail

10021d Detail

...This detail shows accidental drips of glassy woodash glaze on the shoulder. Aha! This is not earthenware; it can only be a high-fired pot from a frequently used wood-fired kiln. The smooth glossy finish was produced by the fluxing effects of wood ash blowing through the kiln at such high temperatures not, as has sometimes been suggested, an applied 'feldspathic' glaze.

![]() 10018 Small tripod jug with handle. 12th -11th century BC Shang Dyn.

10018 Small tripod jug with handle. 12th -11th century BC Shang Dyn.

A simple piece of Shang earthenware pottery. The pointed legs and the spout suggest it was based on a metal form.

![]() 10019 small tripod warming pot. Shang Dyn.

10019 small tripod warming pot. Shang Dyn.

A similar little pot but this one has a thick blob of greenish-brown glass/glaze solidified on the belly. See the detail.

![]() 10020 Detail: glaze drip: small tripod warming pot.

10020 Detail: glaze drip: small tripod warming pot.

Another clear example of molten woodash glaze dripping from the kiln roof onto the pots below and, as the kiln cooled, solidifying into a hard translucent glassy lump.

Many important deductions can be made from an examination of this small pot with its glaze drip:

- The pot was wheel-made using a smooth high-fire(stoneware) body

- The unfired body colour was probably light grey but the high wood-firing together with the fluxing of impurities, such as iron, produced this toasted colour surface.

- The pot has been heated to at least 1150°-1250°C.

- The kiln used was refractory enough for firings in the region of 1200;°C.

- The kiln was wood-fired and had already been used for some time for firing high-fire ware.

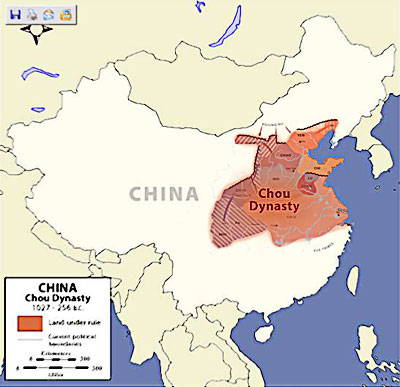

The Chou Era

1027-256BC

Early Chou Ceramics - 10th-8th centuries BC

Glaze Development: Slow, Intermittent, Isolated and Patchy

10127 unglazed tripod pot(li)with three lug-like flanges and flared wheel-finished rim. Western Chou H:14.6cm 10th century BC.CG.

10127 unglazed tripod pot(li)with three lug-like flanges and flared wheel-finished rim. Western Chou H:14.6cm 10th century BC.CG.

During much of this long feudal age, domestic pottery continued to be traditional and generally simple in form and unglazed. Nevertheless, archaeological finds across widely separated areas of China show that at varying times there were potteries which were making glazed high-fire pots.

Chou Potters produce high fire glazes

based on simple mixtures of

Wood ash, Lime and Clay

10112 Glazed Jar with looped lugs.Lo-yang. Western Chou H:21.5cm 10th century BC.CG.

10112 Glazed Jar with looped lugs.Lo-yang. Western Chou H:21.5cm 10th century BC.CG.

One of a group of similar high-fired pots found in 1964; a small storage jar, probably used for fetching water. Made by joining two thrown bowl shapes on a wheel and joining rim to rim, finishing the neck and foot, then fixing the small rope lugs. The shoulder is scratch decorated in a simple ancient zig-zag pattern - neolithic style. The body is fine grained refractory greyish white body. It has been glazed by bushing or pouring a simple chalky clay slip/woodash mixture![]() and then heated in a woodfired kiln to a temperature of around 1200°C. The oily texture and glassy green colour of the fired pot are characteristic of such simple highfire glazes.

and then heated in a woodfired kiln to a temperature of around 1200°C. The oily texture and glassy green colour of the fired pot are characteristic of such simple highfire glazes.

![]() 10043 Small brownish glazed pot T'un-hsi, Anhui. Western Chou H:18.5cm. 9th-8th century BC. CG.

10043 Small brownish glazed pot T'un-hsi, Anhui. Western Chou H:18.5cm. 9th-8th century BC. CG.

This example was also thrown, scratch decorated and dipped, poured or brushed with a 'glaze' as can be seen by the drips around the high spreading foot. The body is a smooth buff stoneware type clay. Again the glaze recipe would have been a simple mixture based on a chalky clay slip and woodash.![]() The colour, texture and fluidity will vary with the differing proportions materials and the amount of iron and/or lime in the clay or ash. The firing patterns would probably vary too. But all these examples show the chacteristics of such simple mixtures which can become glazes at temperatures from 1150-1250°C.

The colour, texture and fluidity will vary with the differing proportions materials and the amount of iron and/or lime in the clay or ash. The firing patterns would probably vary too. But all these examples show the chacteristics of such simple mixtures which can become glazes at temperatures from 1150-1250°C.

![]() 10044 Brownish glazed flagon T'un-hsi, Anhui. Western Chou H:12.5cm. 9th-8th century BC. CG.

10044 Brownish glazed flagon T'un-hsi, Anhui. Western Chou H:12.5cm. 9th-8th century BC. CG.

A small stoneware flagon or jug. Thrown, rib decorated and, when leather hard, brushed or poured with a simple slipglaze - lime/clay/woodash. The brownish colour will be due to iron and lime in the clay or ash. The irregular oily runs and pools, or ripples in the pattern of small ridges, is quite characteristic of such lime/ash glazes.

10125 Small green glazed bowl. Late Western or early Eastern Chou H:5cm. 8th-7th c. BC

10125 Small green glazed bowl. Late Western or early Eastern Chou H:5cm. 8th-7th c. BC

The green-grey glaze on this bowl is produced with the same limited ingredients as the previous examples. The differences in the proportions and varying composition of a clay, lime or ash can account for a seemingly very different glaze, but the oily and frosting effects characteristic of ash/lime glazes are still present.

Bronzes from the late Chou period

![]()

![]() 10039b1-2 Chou bronze vessel with animal handles. Right: detail

10039b1-2 Chou bronze vessel with animal handles. Right: detail

These examples of ceremonial bronzes from the late Chou period show the high quality of workmanship and refinement achieved.

![]()

![]() 1039b3-4 A Chou ceremonial bronze with animal handles. Right: detail.

1039b3-4 A Chou ceremonial bronze with animal handles. Right: detail.

The high quality of fine detail in these bronzes is never equalled in clay copies.

![]()

10107-8 Eastern Chou Bronze monster mask & ring 29cm diam 5th century BC. Right: detail

10107-8 Eastern Chou Bronze monster mask & ring 29cm diam 5th century BC. Right: detail

On bronzes the formalised almost abstract Shang dragon is often replaced during the Chou period by more realistic animal carvings.

Grave Gifts in Fired Clay

from the late Chou Period

(Copies of Bronzes?)

In the late Chou Period ceramic substitutes for bronze grave offerings were on the increase. These examples below, unglazed Chou pottery, part of a new ceramic market - cheaper ceremonial grave gifts which appear much less skillful clay copies of bronzes. They were unglazed but might have applied colouring.

![]() 10045 A three-legged and lidded ceremonial jar with animal handles. Eastern Chou 6th-4th c. BC.

10045 A three-legged and lidded ceremonial jar with animal handles. Eastern Chou 6th-4th c. BC.

The vase shape with its sharp edged rim and the angular cut-out quality of the handles and feet are but poor echoes of an original bronze casting.The moulding details are bold but coarse and the scratched patterns are rough. Overall the potters who made these were much less skilled than the bronze model and mould makers. Most of these clearly lack refinement and finish.

![]() 10046 Detail of Animal handle. Eastern Chou 6th-4th c. BC.

10046 Detail of Animal handle. Eastern Chou 6th-4th c. BC.

The simple chunky cartoon shape of this creature is engaging, but naive. The crude scratched ornament shows the wish to echo the rich metal ornament.

![]()

10047 & 10048 - A lidded vessel closely following the bronze style. Eastern Chou 6th-4th c. BC.& detail of the scratched decoration

10047 & 10048 - A lidded vessel closely following the bronze style. Eastern Chou 6th-4th c. BC.& detail of the scratched decoration

Such pots don't look as if they were made by an expert model and mould maker - a craftsman potter in the bronze industry. This belongs to the lower end of the market: clay copies of expensive bronze grave goods. This were vastly cheaper to make and affordable to a growing middle class market where bronze would often be too costly and bought mostly by the aristocracy.

![]() 10079 Eastern Chou Grey pottery stem bowl 4th-3rd c. BC. MMA.tou with massive lid.

10079 Eastern Chou Grey pottery stem bowl 4th-3rd c. BC. MMA.tou with massive lid.

A simpler bronze form has been copied here, Two bowl forms thrown and then turned with a stem on one and a large knob fixed onto the other. An attempt has been made to decorate the surface with coloured slip.

After the 8th century BC there seems to have been a long gap in the production of glazed pottery and it does not reappear until the period of the Warring States in the late 4th-3rd century BC. It is likely that the surprisingly simple, but very efficient, high-fire cave kiln was used for such firings.

A Brilliant Oriental Invention

|

Eastern Chou High-fired Pottery

10040 & 10041(Detail) A stamp decorated storage pot Eastern Chou ca.4-3th c. BC.Warring States Period BML.

10040 & 10041(Detail) A stamp decorated storage pot Eastern Chou ca.4-3th c. BC.Warring States Period BML.

A simple coiled and smoothed globular storage pot made in the typical pale grey/buff body and stamped when leather hard. Textile pattern produced by repeated use of a carved wooden stamp or roller.

10042a & b Eastern Chou ca.4-5th c. BC.

10042a & b Eastern Chou ca.4-5th c. BC.

Two views of another similar form with a stamped pattern. On this pot there are two 'bronze type' lugs for rings or rope. Of more interest is fact that it has been slip-glazed. The brownish black colour suggests to me that the glaze recipe was either(1)a simple mixture of local clay slip with woodash stirred in and poured over (after stamping the leather-hard pot); or (2)just a red clay slip poured over, when the high temperature and woodash blowing through the kiln would melt the red slip. Either could have produced the brown/black smooth-glazed surface quality.

Southern High-fire glazed ware

10111 High fired Lidded bowl Greenish-brown glaze Southern type Chou H:16.5cm. 4th-3rd century BC.

10111 High fired Lidded bowl Greenish-brown glaze Southern type Chou H:16.5cm. 4th-3rd century BC.

Such wares as this are often described as 'Southern' and are mainly from Chekiang or Kuangtung. This is a well-made covered bowl thinly thrown and the parts expertly luted together. The body used is finegrained and greyish. It has a spreading foot-ring and an upstanding flared collar decorated with elaborate slit perforations. The lid is neatly made with a central knob and decorated with incised bands of zig-zag pattern. The simple slip-glaze is probably lime/(red?)clay/woodash type and was brushed on or poured over when leather hard. The irregular oily greenish translucent colour where thick and less shiny browny-black or rusty colours when thin are quite characteristic. Fired at 1180-1250°C. Such well-made and finished high-fire thrown pottery indicates that considerable advances in ceramic development are now beginning to happen in some parts of the country. There is evidence that there was a long established high-fire tradition in Chekiang province which from now on begins to show marked improvements in almost every respect. The colour and crisp outlines of this form closely imitate metal. The sharp changes of direction from the conical neck flange to globular body to conical foot, all show how important the bronze metal influence was on a potters work. Even the glaze colour suggests bronze. This influence will continue down the ages in China.

The Late Chou Era

New Teachings, New Techniques & New Influences.

The Iron Age

10053 Left. Iron half-moulds for casting axe heads.L:28.6cm.

10053 Left. Iron half-moulds for casting axe heads.L:28.6cm.

& 10054 Right. Iron twin mould - possibly for casting sickle blades. L:32.5cm ca.5th-4th. c.BC.

It was around 500BC that Iron began to be smelted in China; it was probably introduced from the West. But unlike the West, the Chinese soon learned how to cast iron - a technique which remained virtually undeveloped in the West until at least the 13th century AD. Bronze was regarded as an aristocratic metal in Shang and Chou China, and although used for centuries for ceremonial use, was never used for common agricultural tools which until the coming of iron were still made in wood. Now in the 4th c. BC. cast iron began to replace many such wooden tools. The iron hoe, for example, resulted in a rapid improvement in agricultural production. Note: Experts are not agreed as to how these two iron moulds here were actually used.

Warring States Period

476-221BC

Although this period was plagued with small wars, political and social instability, the fluid situation encouraged trade, cities grew and foreign influence increased. Change and new ideas were becoming fashionable.

Confucius and Lao-tse

The lives and teaching of two great Chinese philosophers or thinkers, Confucius and Lao-tse, began to influence the social, cultural and spiritual life of the Chinese people from now on. They taught two quite distinct ways of living in society. Both teachings have had an enormous influence on most aspects of Chinese culture ever since.

Terracotta Roof Tiles

10068 Decorated roof tile from the eaves. 5th-4th.c.BC.

10068 Decorated roof tile from the eaves. 5th-4th.c.BC.

Ceramic roof tiles appear for the first time in place of thatch or shingle. The production of such quanities of decorated end tiles suggests that more richly decorated permanent houses were being built for the rapidly growing middle classes - scholars, civil servants and merchants.

10069 Detail of pressed design on the end tile

10069 Detail of pressed design on the end tile

The tile end decoration was usually press-moulded

Enamels, Glass & Lead Glaze

now arrive from the West

- and are soon copied

10056 A group of glass and ceramic beads. 4th-3rd c.BC.

10056 A group of glass and ceramic beads. 4th-3rd c.BC.

Chinese glass and ceramic beads. These were probably copied from imported Middle Eastern examples. Glass was little used in China. Its popularity towards the end of the Eastern Chou period was probably due to the great increase in foreign trade and influence. The same can be said for the bowls below.

10050 Eastern Chou Red earthenware slipped and inlaid with glass 4th-3rd c. BC.

10050 Eastern Chou Red earthenware slipped and inlaid with glass 4th-3rd c. BC.

Such small red earthenware bowls, glass or frit paste decorated, were made towards the end of the Eastern Chou period around 4-3rd century BC. Much of the bright colour has rotted away with time and damp conditions or simply not been fired high enough to melt the frit.

10051 Eastern Chou Red earthenware slipped and inlaid with glass 4th-3rd c. BC.

10051 Eastern Chou Red earthenware slipped and inlaid with glass 4th-3rd c. BC.

The bowl was covered with a white slip and then inlaid with glass paste. It was probably intended to copy a more precious and possibly foreign vessel in bronze or even silver.

10052 Eastern Chou Red earthenware slipped and inlaid with glass 4th-3rd c. BC.

10052 Eastern Chou Red earthenware slipped and inlaid with glass 4th-3rd c. BC.

This detail shows the rich red colour of the body. The neck and parts of the body are painted with white paste. The black paint probably contained iron and copper. The bluish colour is probably copper.

An unusual metal form copied in clay

![]() 10049 Eastern Chou Vase with spiral decoration 3rd -2nd c. BC.

10049 Eastern Chou Vase with spiral decoration 3rd -2nd c. BC.

This last example of Chou pottery emulates a beaten metal(Copper, Silver, Gold) form, not a cast vessel. This sophisticated piece of pottery has more in common with the rhythms and swirling shapes of contemporary celtic designs than any Chou pot I know. Can the original model have been imported from across the Steppes? In any case, it is a most refined and finished clay vessel with handles and ornament totally integrated into the whole form. making it perhaps the most beautiful piece of unglazed pottery of the late Chou period.

What are the origins of Lead glazes in China?

10110 Greenish Lead glazed earthenware jar with moulded decoration diam:22.2cm 3rs century BC. KNGA

10110 Greenish Lead glazed earthenware jar with moulded decoration diam:22.2cm 3rs century BC. KNGA

The origin of lead fluxed glazes in China is shrouded in mystery - was it introduced from the Near East or was it an independant development? The Near Eastern Empires, Alexandrian and Roman Cultures were already making such glazes before they appeared in China. Whatever the exact composition of this glaze, it is intended to imitate bronze metal. The shape too, and the addition of the crisp lugs and the band of raised pattern which masks the join of two bowls (done with a carved pattered roller) make this pot appear as if made of this expensive metal. Real rich lead glazes would appear soon in the Han dynasty